Materials Management

No matter what you need, we make it happen!

![]()

In our materials management we have a wide range of tasks and see ourselves as an internal service provider. We are the link bet ween our suppliers, assemblers and you as a customer.

The tasks start with the demand oriented procurement of goods and services. Once an order has been placed, compliance with deliv ery deadlines is monitored until the goods are received. Subsequently, a quality inspection takes place. Only after the inspection has been completed and, in the cas e of articles subject to inspection, recorded in our database, are the goods received forwarded to the internal flow of goods.

It continues with the stocking and management of our own warehouse, where the most common, but also strategically important or critical spare parts are stored to ensure the best possible machine availability for you as a customer and to be able to act quickly.

The area of responsibility is rounded off by the outgoing goods department. The goods are then securely packed and handed over to parcel services or freight forwarders.

Take advantage of TDK’s spare parts service – From ball bearing to drive control

You have a machine breakdown and urgently need a spare part ? No matter if it is standard components or specific machine parts: Our stock is well sorted. We are happy to accept your inquiries. Here is a small excerpt of the makes:

Standard components:

- Siemens

- Bosch

- Festo

- IFM

- Balluf

- Euchner

Machine parts:

- Index / Traub

- MAG (Hüller Hille / Hessapp / Diedesheim

- Stama

- LTA

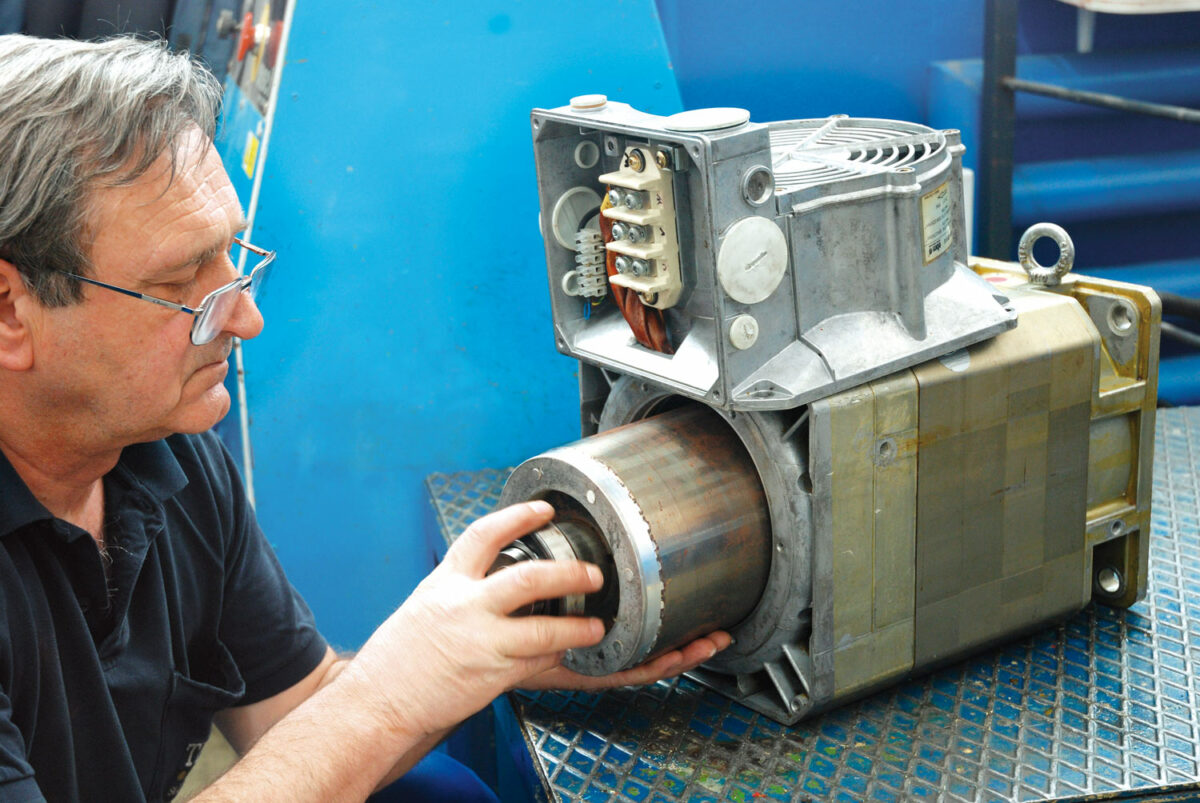

Electric motors repair of three phase and servo motors (AC/DC)

Certified and professional engine repair so that everything runs smoothly for you

Our location TDK Slovakia Považská Bystrica has been an authorized service partner of Siemens in the field of motor and drive repair since 2001. This includes, for example, all drive motors of the FT and FK series as well as the spindle drives of the PH series.

In addition, we also repair AC and DC drive motors from other manufacturers as well as conventional three phase motors up to 250 KW.

In our workshop we have all the machines necessary for mechanical overhaul. We have immersion baths and drying ovens for insulation, but also test benches for the final performance test of drives from the manufacturers Siemens and Lenze.

All engines undergo thorough performance testing before they leave our workshop.

TDK Technische Dienste Kleinschmidt GmbH

a company of the 2K Group

We are BG and DIN ISO certified service providers

Navigation

Service

Legal notice

Thorben Kühn

Thorben Kühn